Composites Engineering Support

"Convert rough ideas into viable

FRP composite products"

CSS' Composites Engineering Support services focus on carbon and fiberglass composite product development efforts typically with complex shapes and challenging fiber architecture:

- Irregular Geometries

- Hollow Cross Sections

- Closed Profiles (e.g. Hoops, Rings)

- Nested or Telescoping Structures

- Co-Molded Inserts

- Hybrid Processing Methods

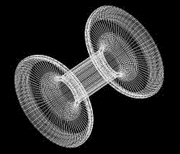

FRP Composite Spool

Product Design and Process Development

CSS' Composite Davit project, like most Engineering Support efforts, is an amalgam of composite product design and process development support.

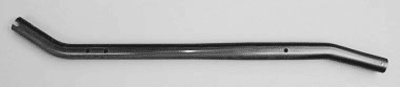

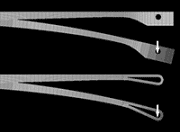

Lightweight Multi-Section Composite Davit

CSS utilizes Computer Aided Design (CAD) and basic Finite Element Analyses (FEA) tools to predict structural performance and optimize the composites design for the specified geometry ... or optimize part geometry for improved performance and/or ease of production.

Composite prototype fabrication trials may be conducted by CSS, by the Client with CSS support, or by a prospective composites manufacturer to validate the composite tooling design and manufacturing approach.

CSS' Composites Manufacturing Support services help Clients transition successful product or process development efforts to full-scale in-house FRP composites production.

High volume production needs may be met by utilizing CSS' Composites Overseas Sourcing Assistance services which facilitate procurement of composite components and value-added assemblies from vetted overseas manufacturers.

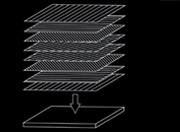

Bladder Inflation Molding

CSS also helps Clients design and develop simple to complex prepreg and resin infused Bladder Inflation Molding (BIM) composite products. CSS' bladder molding services include custom bladder development, tooling design, composite product design and bladder molding manufacturing support.

BIM Composite Stroller Frame Member

Collaborative Engineering Support

Theoretical and laboratory intensive product or process development efforts may be supported through CSS' affiliation with the University of Delaware's internationally recognized Center for Composite Materials (CCM) which provides Client access to state-of-the-art composite laboratories, prototype fabrication facilities and research professionals.

Research and IP Development

Pure research and exploratory development efforts frequently answer a fundamental challenge; are FRP composites the best material choice for my application?

Design & manufacturing trade studies, scale process demonstrations and performance evaluations are used to identify the best composite material, design approach, and manufacturing method for each application.

CSS' Intellectual Property (IP) development efforts refine composite product concepts and provide assistance securing patent protection including competing product analyses, patent and prior art searches, and content development for patent applications.

"FRP composite material, product design or production viability questions? We look forward to providing experience backed answers and solutions to simple or complex composite project problems!"