Composites Overseas Sourcing Assistance

"Hassle-free sourcing of FRP

composite products made in China"

CSS' Composites Overseas Sourcing Assistance services help Clients source consumer, industrial and medical fiber reinforced polymer (FRP) composite components, finished products and value-added assemblies made in China ... with fewer headaches and less uncertainty.

CSS Clients have imported more than $10M of composite products (retail value over $45M) while realizing significant net unit and production tooling cost savings.

Import FRP Composite

Products With Confidence

CSS introduces Clients to vetted composite manufacturers possessing the required manufacturing expertise and capacity to meet current as well as future production demand. Furthermore, CSS mitigates sourcing risk by managing overseas production and troubleshooting issues on the Client's behalf ... from sample development through Purchase Order fulfillment.

Overseas Sourcing Assistance Services

- Vendor Communication Management

- Production Cost Estimates

- Tooling Design & Development

- Sample Definition & Development

- Product Test Development

- Product Specification Development

- Production Line Qualifications

- Production Quality Control

- Purchase Order Placement

- Production Schedule Coordination

- Production Trouble Shooting

- Shipment Coordination

- Product Quality Resolution

CSS' Overseas Sourcing Assistance services can be tailored to support new product procurement needs or existing product alternate supplier qualifications. All composite designs are reviewed for ease of overseas manufacture and the ability to effectively control product quality. Where possible, CSS will recommend material and/or design changes to improve production efficiency and in turn reduce manufacturing cost.

Clients may also utilize CSS' Composites Engineering Support services to refine a rough product concept or Composites Manufacturing Support services to optimize a manufacturing process prior to venturing overseas.

High Volume

Composite Tubing Production

And Value-Added Shaft Assembly

Vetted overseas suppliers use table rolling over rigid mandrels and oven curing or Bladder Inflation Molding in heated platen presses tooling to produce hollow composite structures such as arrow shafts, push rods, paddle shafts, golf shafts, ski poles, canes, booms, posts, armatures, bicycle frames, bats, handles, wheelchair frame members, and other challenging hollow shapes.

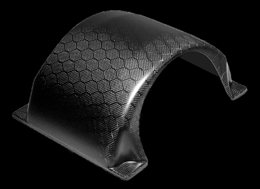

Complex FRP Composite Geometries

With High Quality Finish Requirements

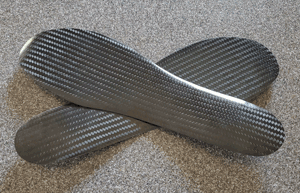

Vacuum forming, compression molding, and autoclave consolidation are used to produce flat and contoured FRP composite products such as covers & guards, flat springs, insoles, RC and UAV parts, radiolucent structures, and various stiffened skin and sandwich panel structures.

High Volume

Composite Insole Production

Note: In-house or contracted CNC machining capability is available to support trimming, drilling and other precision value-added machining operations.

CSS also facilitates sourcing of affordable stamped and CNC machined metal parts from vetted machine shops in China.

High Volume CNC Machined

Metal Part Production

"Curious about overseas production costs? CSS can provide preliminary overseas production tooling and unit cost estimates at no charge given anticipated order volume and sufficient product design detail."